|

|

Using

Acetic Acid Rinse as a CCP for Slaughter

by

Chris Kerth and Crystal Braden

Auburn

University Department of Animal Sciences

|

|

Introduction

|

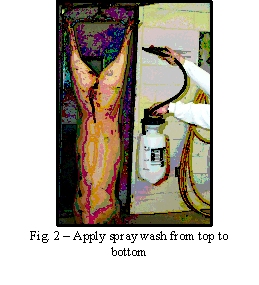

| The procedures recommended for developing HACCP (Hazard Analysis Critical Control Points) systems depend on the subjective assessment of risks, with consequent identification of critical control points (CCPs) for the control of biological, physical and chemical hazards (1). Microbiological hazards are the major concern in the production of raw meats at the packing plant (1). Fecal contamination from the external surface of the animal and cross-contamination from knives and hands that have been in contact with punctured GI tracts and animal surfaces cause the carcass to become contaminated. Subsequent processing of the carcass (including cutting, injecting, and grinding) carry these contaminants to the interior of the meat products and increase the hazard of human sickness and product spoilage from these microbes. Therefore, the prevention and control of microbial contamination during the harvesting process is crucial and is most always included as a CCP in slaughter HACCP plans. These hazards can be controlled by the implementation of microbial interventions. Several intervention strategies have been tested and/or adopted for use in eliminating both pathogenic and spoilage bacteria from carcass surfaces. Some interventions include steam vacuuming, hot and ambient temperature water washes, trimming, and application of organic acids. Solutions of lactic and acetic acid are commonly used by the slaughter industry as antimicrobial spray wash interventions to reduce the microbial load on freshly slaughtered carcasses (2). Research (3, 4) has shown significant reduction of microbes on fresh meat carcass surfaces after the use of an acetic acid spray of 1.6% or higher. This concentration of acetic acid is capable of significantly reducing the pH of the carcass surface by as much as 3.5 units, (5) making it difficult for microbes to survive. According to the American Association of Meat Processors, an initial warm carcass wash is important to assist in removing as much organic matter (manure, hair, etc.) from the carcass as possible before continuing hot water or acid rinses. The warm 90-105°F water temperature is also important to keep the carcass surface warm, in the event that acid rinse will follow. Research has shown that the higher the pressure that is used to spray warm water the better. While 300 psi might be difficult for some to obtain, the portable spray units that some small processors have, should reach that level of pressure. It is important that steps be taken to prevent this high pressure warm water treatment from blowing fecal contamination all over the slaughter floor. This would be prevented by proper training for those using the sprayer and/or the use of some type of panels or walls to surround the carcasses while being washed. Hot water pasteurization has been shown to be an affective means to reduce E. coli levels on beef carcasses; however, it may be difficult to use water of this temperature on carcasses in some plants. Acetic acid wash would be recommended over lactic acid at this time due to its availability and safety. Initially, it is recommend that vinegar be used, from a grocery store (5-8% acetic acid), diluted to at least 2% concentration. Use of chlorine is not recommended as the research is inconsistent in terms of its affect on pathogens. There is also verv little research using 50 ppm chlorine solutions on carcasses. Additionally, chlorine is very corrosive and may cause damage to equipment and facilities over prolonged exposure and direct handling. Inhalation of chlorine may also cause a hazard to plant workers. Acetic acid, also known as ethanoic acid or glacial acetic acid is a stable substance. However, in its pure form, it is highly flammable and corrosive (refer to Fisher Scientific MSDS # 64-19-7). For this reason, it is important to identify a means to obtain a small amount of the substance without having to handle it in its pure form. Acetic acid is the active ingredient found in household vinegar. Normal white household vinegar will contain about five percent acetic acid (refer to product label). Using normal household vinegar to obtain small concentrations of acetic acid is both safer and more convenient than using pure acetic acid. When applying acetic acid to pork carcasses, it is preferable to apply the treatment at an early stage of dressing when little or no muscle has been cut (1). Application of an acetic acid wash may take place pre-evisceration (3, 6). To counter the undesirable microbiological effects of operations on the head, treatment should be applied after, rather than before removal of the head (1). Acid washes may also be applied as a rinse to the entire surface of the carcass (7). Low-pressure, hand held sprayers may be used to administer acetic acid washes in the small abattoir (2, 3, 4, 5, 6). Administration of an acetic acid spray wash proves to be an effective means of microbial reduction on the carcass surface. Inclusion of this practice into the HACCP plan of the small abattoir can ensure adherence to food safety objectives (FSOs) or recommended levels of microbial contamination considered acceptable for consumer protection (1). |

|

Materials and Methods

|

1 part Water

+ 1 part Vinegar (5% Acetic Acid)

.

|

|

Other Considerations

|

|

While most household vinegar is 5% acetic acid, always check the label to insure that the proper final concentration of acetic acid is reached. It may be necessary to obtain a letter of guarantee from the manufacturer of the vinegar and a Material Safety Data Sheet should be kept on file for vinegar and/or acetic acid for worker safety. Only use a brand new sprayer and check with the manufacture of the sprayer to determine if it is composed of only materials the FDS considers acceptable for incidental food contact. Provide the manufacturer's specified use information to the inspector if requested. Clearly mark the sprayer. |

|

References

|

|

Bryant, J., D.A. Brereton and C.O. Gill. 2003. Implementation of a validated HACCP system for the control of microbiological contamination of pig carcasses at a small abattoir. Canada Veterinary Journal. 44:51-55. Berry, E.D., and C.N. Cutter. 2000. Effects of acid adaptation of Escherichia coli O157:H7 on efficacy of acetic acid spray washes to decontaminate beef carcass tissue. Applied and Environmental Microbiology. 66:1493- 1498. Bacon, R.T., J.N. Sofos, K.E. Belk, J.O. Reagan and G.C. Smith. 1999.Commercial evaluation of multiple-sequential interventions for decontamination of beef carcasses. Beef Program Report. Department of Animal Sciences Colorado State University. Cutter, C.N. 1999. Combination spray washes of saponin with water or acetic acid to reduce aerobic and pathogenic bacteria on lean beef surfaces. Journal of Food Protection. 62:280-283. Dorsa, W.J., C.N. Cutter. 1998. Long-term effect of alkaline, organic acid or hotwater washes on the microbial profile of refrigerated beef contaminated with bacterial pathogens after washing. Journal of Food Protection. 612:300-306. Bacon, R.T., K.E. Belk, J.N. Sofos, R.P. Clayton, J.O. Reagan and G.C. Smith. 2000. Microbial populations on animal hides and beef carcasses at different stages of slaughter in plants employing multiple-sequential interventions for decontamination. Journal of Food Protection. 63:1080-1086. Huffman, R.D. 2002. Current and future technologies for the decontamination of carcasses and fresh meat. Meat Science. 62:285-294. |

|

Supported by: Non-Assistance Cooperative Agreement #FSIS-C-33-2003, Development of a Virtual Library for Small and Very Small Meat and Poultry Processors | ||

|

|

| |